How to Heat Press PVC Patches on Hats: A Step-by-Step Guide

Adding custom PVC patches to hats is a fantastic way to create custom designs that stand out with vibrant colors and long-lasting durability. Whether you’re working with baseball caps, trucker hats, or other blank apparel, heat pressing PVC patches ensures a secure and professional finish. From custom PVC patches for personal use to creating custom hats for businesses or teams, the process is straightforward and delivers excellent quality.

For those using heat press machines for the first time, understanding the application process and tools involved is essential for achieving the best results. In this guide, we’ll walk you through the step-by-step guide for heat pressing PVC patches on hats, ensuring your custom patches adhere perfectly for any project or occasion.

Key Takeaways:

- PVC patches are tough and bold: flexible, weather-resistant, and color-rich, which is ideal for baseball hats.

- Set up right: a hat press is best for curved pressure (an iron can work); clean the area, tape the patch, and use a foam pad.

- Press settings: 270–300°F, 10–30 seconds, firm, even pressure (follow your patch maker’s specs).

- Lock the bond: let it cool fully. This is important to cure the caps.

- Validate & care: test on a sample, avoid overheating/under-pressing/uneven pressure, then spot-clean and skip high-heat drying.

Want to produce custom PVC patches?

What Are PVC Patches and Why Use Them on Hats?

Understanding PVC Patches

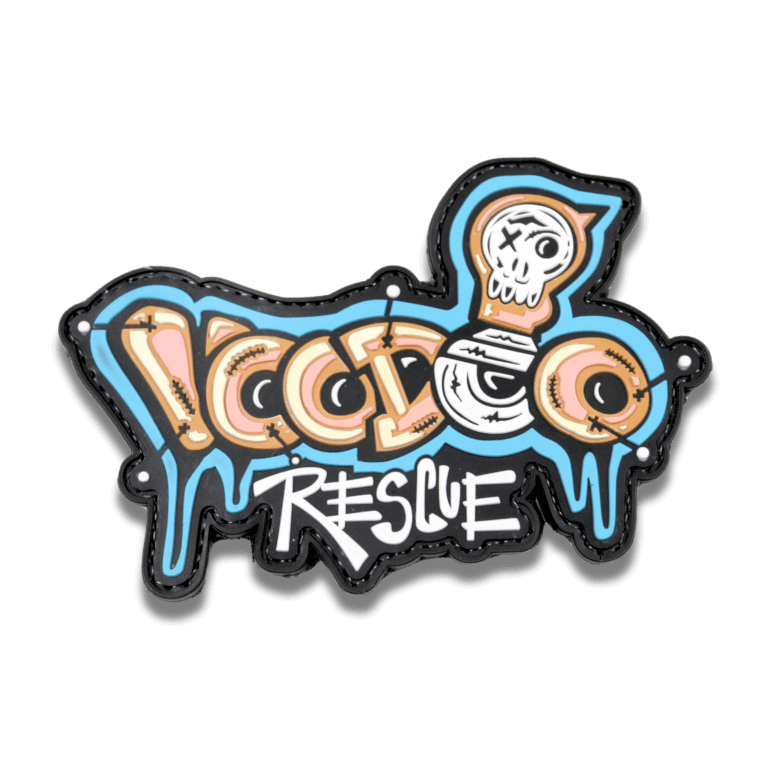

PVC patches are a durable and flexible patch type made from soft, rubber-like material that offers vibrant colors and unique designs. These patches are perfect for showcasing detailed artwork, logos, or text with a 3D effect that stands out. Popular for various applications, PVC patches are commonly used on customized hats, military uniforms, and law enforcement gear due to their resilience and professional appearance.

Custom PVC patches can be tailored to suit specific needs, whether for branding, team uniforms, or personal projects. With multiple backing options, such as velcro or adhesive backing, they are versatile and easy to apply. Their durability makes them an excellent choice for golf hats, ensuring they maintain their quality over time.

Benefits of Using PVC Patches on Hats

PVC patches offer several advantages when used on hats. First, their vibrant colors and detailed designs enhance the overall look of baseball caps, trucker hats, and other blank apparel. Whether you’re creating custom embroidered patches, chenille patches, or using heat-transfer labels, PVC patches add a unique and eye-catching touch.

Additionally, PVC patches are ideal for projects requiring great quality and longevity. They are weather-resistant and maintain their shape and color over time, making them suitable for both personal use and professional applications like law enforcement or military uniforms. Their flexibility also ensures they conform well to the curved surface of hats, allowing for a seamless application.

Essential Tools for Heat Pressing PVC Patches

To achieve the best results when heat pressing PVC patches on hats, it’s important to have the right tools. A hat press is the best option for this task, as it is specifically designed for working on curved surfaces like caps. We use the HotTronix IQ 360 because it has top and bottom heat, which is key when heat-applying PVC Patches.

Heat-resistant tape is essential for securing the patch in place during the heat application process. A teflon sheet is another must-have, as it protects both the patch and the hat from direct heat, ensuring an even and safe application. Heat transfer patches or heat-transfer labels are crucial for ensuring the patch adheres securely to the fabric.

Step-by-Step Guide to Heat Pressing PVC Patches on Hats

Preparing Your Hat and Patch

Before starting, clean the patch area on the hat to remove any dust, dirt, or oils that could prevent proper adhesion. Once the surface is clean, position the custom PVC patch in the desired location. Use heat-resistant tape to hold the patch securely in place, ensuring it doesn’t shift during the heat application process. Be sure to check the hat material to ensure compatibility with high heat. Certain materials can get damaged when they come into contact with high temperatures. We see this a lot with certain types of dad hats and unstructured caps.

Using the Heat Press Machine

Preheat your hat press to the recommended temperature for PVC patches. Generally, a temperature range of 270°F to 300°F works well, but always follow the manufacturer’s guidelines for your specific patch type. Place the hat on the curved surface of the press, ensuring it is securely positioned to avoid movement during the process.

Cover the patch and hat with a foam pad to protect them from direct heat. Apply consistent pressure settings and heat for approximately 10 to 30 seconds. The heat-activated adhesive on the back of the patch will bond with the hat, creating a strong and durable connection. If you’re using velcro backing with iron-on backing on the back of the hook side of the velcro, ensure it aligns correctly with the adhesive surface for a secure fit.

Finishing Touches

After applying heat, allow the patch to cool completely before handling the hat. This step is crucial as it ensures the adhesive sets properly, providing long-lasting durability. Once cooled, inspect the patch application to ensure it adheres evenly and securely to the hat. If you notice any issues, consider reapplying heat or using a sew channel and sewing the patch for additional reinforcement. With these steps completed, your custom PVC patch will be securely attached, ready to show off its vibrant colors and unique design.

Other Customization Options and Patch Types

In addition to PVC patches, there are several other patch styles and customization options to consider for hats. Iron-on patches are a popular choice for their easy application process, while custom chenille patches offer a textured, retro look. Faux leather patches and genuine leather patches add a premium feel to custom hats, making them ideal for high-end designs.

For businesses or organizations, custom embroidered patches are a timeless option, providing a classic and professional appearance. Custom stickers and t-shirts can also be created using screen printing or sublimation ink, offering additional branding opportunities.

When selecting patch styles, consider the specific needs of your project. For example, velcro backing is ideal for patches that need to be removable, such as those used on military uniforms or law enforcement gear. Heat-transfer labels and heat press patches provide a permanent solution for hats that require long-lasting durability. With so many customization options available, the possibilities for creating unique and vibrant designs are virtually endless.

Ready to Start a PVC Patch Project?

Tips for Achieving Professional Heat Press Results

To achieve professional-quality results when applying PVC patches, it’s essential to experiment with different patches and patch designs. Each patch type may require slight adjustments in temperature, pressure settings, or application time to ensure the best results. Always test the process on a sample hat or patch before working on your final product to avoid mistakes.

When ordering in bulk, keep in mind factors like minimum order quantity and the number of business days for production and shipping. Opt for fast delivery and free shipping options when possible to save time and costs. This is particularly important for businesses or teams with tight deadlines, such as soccer teams or law enforcement units requiring uniforms.

Finally, always double-check the compatibility of your tools and materials. Ensure your hat is suitable for the curved surface of hats and that your foam pad and heat tape are in good working condition. By following these tips and using the best tools, you can consistently produce great-quality custom hats that stand out.

Making the Most of PVC Patches for Custom Hats

PVC patches are a versatile and durable option for creating custom hats that suit various purposes, from personal use to professional applications. They are ideal for projects involving sports teams, such as soccer teams, or for official uniforms used by law enforcement and space force personnel. Their vibrant colors and unique designs make them a standout choice for customization.

Whether you’re using heat press machines or embroidery machines, the customization options for hats are nearly limitless. By leveraging high-quality materials, exploring different patch styles, and following a precise application process, you can ensure your custom hats deliver great quality. With the right tools and techniques, PVC patches can elevate any design, making them perfect for custom orders or personal projects alike.

Eric Turney

Eric Turney A devoted father, football fanatic, and stand-up comedy enthusiast who loves nothing more than bringing people together over great food and a good time. When he’s not cheering on his favorite team or experimenting in the kitchen, you can find him connecting with others on LinkedIn